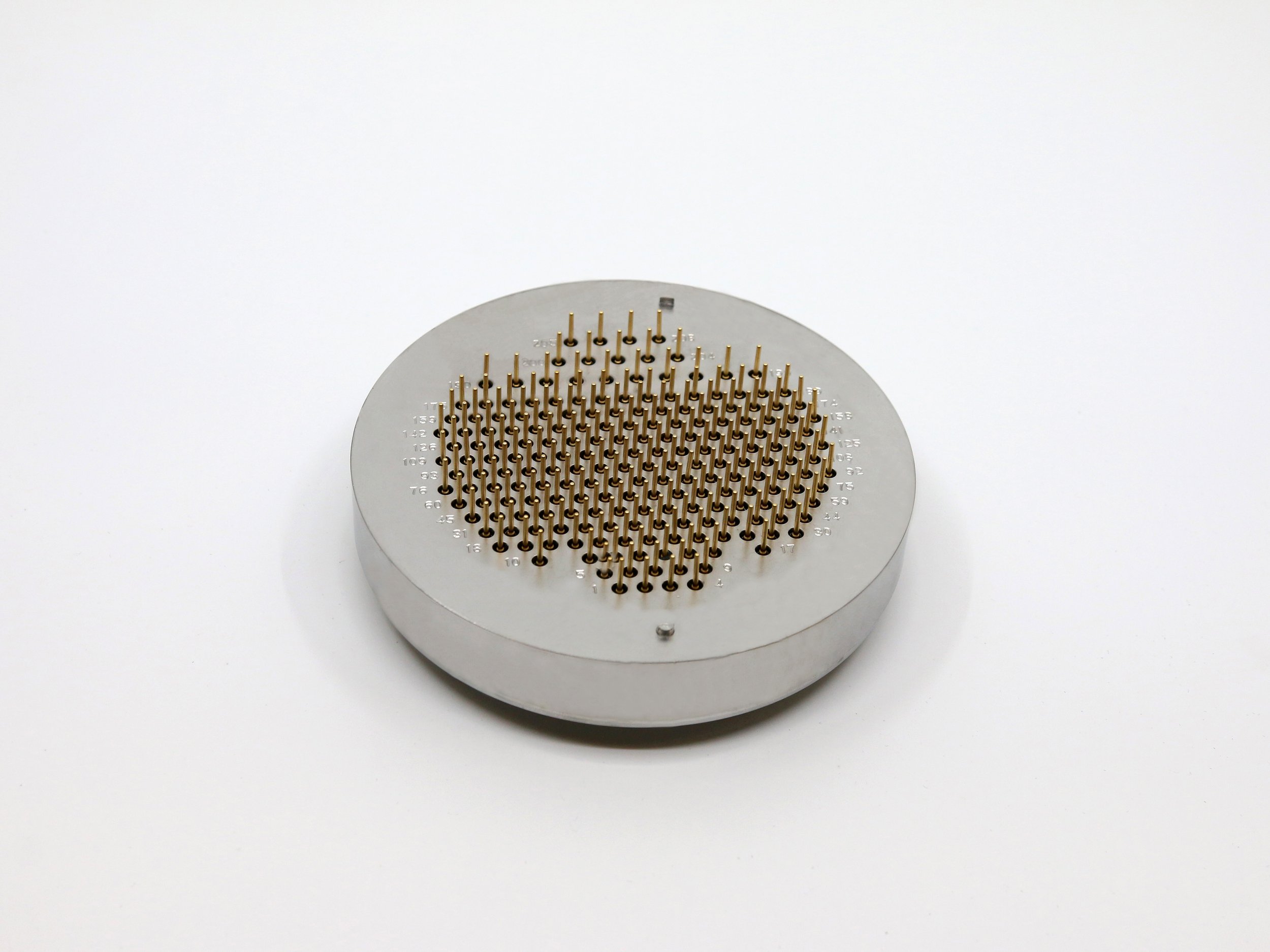

Our housings are fabricated using a one-piece shell construction for ultimate strength and performance. Polarizing keys, bayonets, and other hardware are machined in, providing a more robust product with long-term reliability.

Circular Connectors

TECHNICAL DATA

Materials (shells):

Stainless Steel, Titanium, Kovar, Monel, Aluminum, high nickel alloys, and Inconel. RoHS compliant materials and certification available .

Materials (Contacts):

Iron Nickel Alloy, 52 Alloy, Kovar, Brass, Beryllium Copper, Platinum, and other types of Copper Alloy materials. RoHS compliant materials and certification available.

Hardware Mounting Configurations:

Bulkhead mount, box mount, jam nut mount or flange and weld mount for laser welding. Post machining capability for titanium and kovar welding requirements.

Terminations:

Flatten and pierce or eyelet, flying lead, solder tail, solder cup, solder pot, and all are available with solder dip coating.

Testing:

Leak Rate (1x 10-9 cc/sec helium at 1 atmosphere differential) and pressure testing up to 90,000 PSI, electrical continuity, dielectric withstanding voltage (DWV) per Mil-Std 1344 and insulation resistance (IR) validation at temperature per Mil-Std 202.

Tolerances:

Less than .001" are achievable on finished assemblies, please consult the factory for details.